Ballast Water Treatment System (BWTS) Installation

Ballast Water Treatment System Stages

Get a Quote For Your Project

1. 3D Laser Scanning

PSA Marine Bureau’s experienced Engineers perform onboard a highly accurate (±1-2mm) 3D-LASER SCAN of the engine room and check all relevant technical details for available passage for rigging the equipment onboard. The generated point cloud helps for drawing in 3D drawing software not only all the possible installation arrangements but also the pipping and cabling paths.

More

3D Scans are performed with the use of 3 state-of-the-art laser scanners for the first stage of water ballast systems.

- FARO FOCUS M70

- FARO FOCUS S120

- BLK 360

Deliverables:

- 3D Point cloud data in .rcp/E57/.fls format

- Detailed visit report

- Video/photos

2. Engineering Study

After the 3D-Laser Scan is finished we procced to the second stage of water ballast treatment system installation. In the 2nd stage, the collected data and pictures are gathered and used to generate an accurate 3D representation of the scan areas in which detailed engineering drawings of the selected system can be made, including:

- 3D representation of the scanned areas

- 3D water ballast system virtual installation

- 3D Piping routing & Outfitting modifications

More

After finishing our 3D model an engineering report is made for the ship owner to comment on the design and to conclude to the best possible solution for each case, which includes:

- Isometric drawings of all the piping

- Needed modifications on the vessel

- Cabling path design

- Valves

- Reducers

- Limit switches

- Cabling list: type of cable/meters

- Time and money requirements for the installation

- Risk analysis

After the required changes are made the final design is approved by the customer. Then the ship owner can decide on the implementation of the system.

3. Feasibility Study

After the completion of the 3DLS and the registering of the scan data we proceed to feasibility study

(for each of the candidate water ballast systems)

More

- Compilation of Possible Installation Scenarios

- Examination of available resources (i.e. power, pressure head)

- CAPEX & OPEX comparison table

- Optimal arrangement of the new water ballast equipment

- Routing for essential piping of the system

- Equipment foundation

- Possible relocation of exist. equipment & examination of most suitable relocation areas

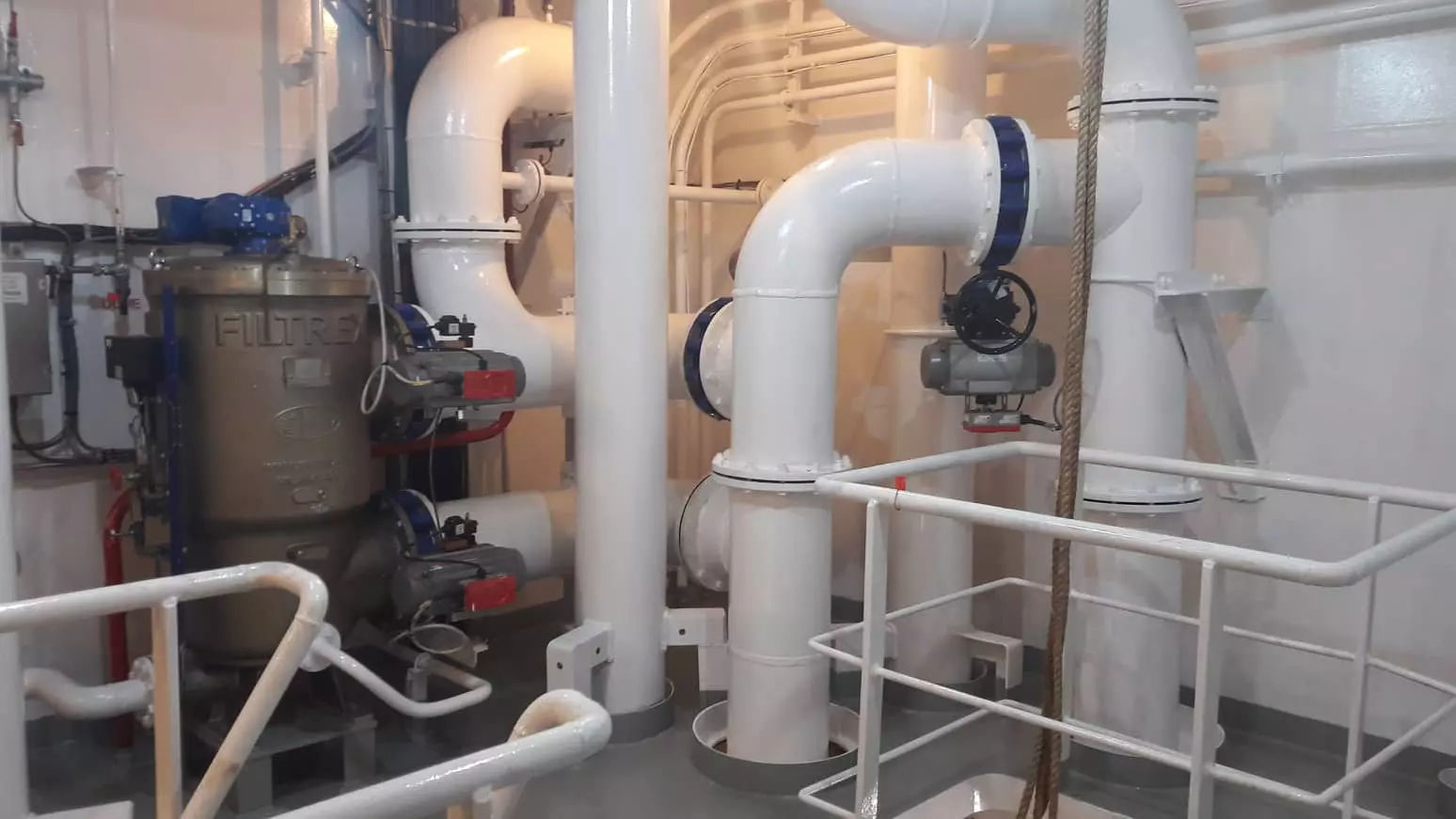

4. Installation

If the customer decides to proceed with the installation of the water ballast proposed system our company offers:

- Preparation of all required drawings for Classification Society and Flag State approval

- Preparation of technical specification of modification, in order to be submitted to various shipyards for quotation

More

- The construction details of the new piping system shall be designed in accordance with international manufacturing standards for the purpose of pre-fabrication, in order to be ready for onboard installation during the ship’s stay at dry dock/shipyard.

- A detailed list including pipe components & fittings as well as all necessary connection cabling shall be prepared for pre-ordering / quoting purposes

- Communication with the class surveyor for class approval

- Attendance during dry dock for proper installation of the system

- Installation of the system

Latest Projects

M/T "ALIGOTE"

BWTS

ROXANA SHIPPING

TECHCROSS EXECS

1600X1

CLASSLR

"SARONIC SPIRE"

BWTS

SEA SPIRE

ERMA FIRST

1X600

CLASSNK

M/T "ALKIMOS"

BWTS

CAPITAL SHIP MANAGEMENT

ALFA LAVAL PURE BALLAST

3.1 600

CLASSBV