Retrofit Studies

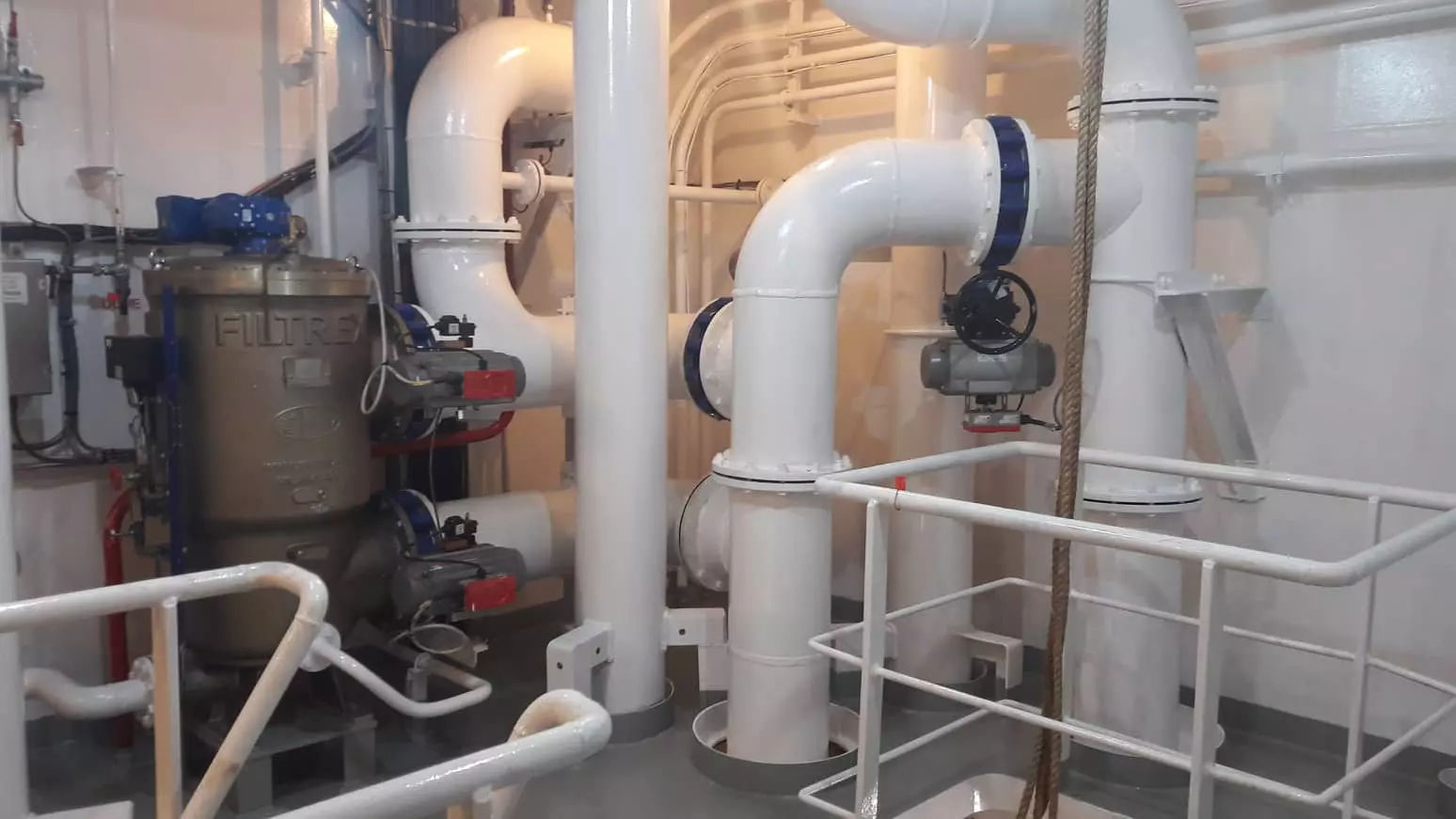

Carbon Capture and Utilization System, Exhaust gas cleaning system, Ballast water treatment system, cargo system modification, yacht outfittings & modifications,

Get a Quote For Your Project

1. 3D Laser Scanning

PSA Marine Bureau’s experienced Engineers perform onboard a highly accurate (±1-2mm) 3D-LASER SCAN of the engine room and check all relevant technical details for available passage for rigging the equipment onboard. The generated point cloud helps for drawing in 3D drawing software not only all the possible installation arrangements but also the pipping and cabling paths.

More

3D Scans are performed with the use of 3 state-of-the-art laser scanners for the first stage of water ballast systems.

- FARO FOCUS M70

- FARO FOCUS S120

- BLK 360

Deliverables:

- 3D Point cloud data in .rcp/E57/.fls format

- Detailed visit report

- Video/photos

2. Feasibility Study

Using the data from the 3D laser scan the best possible way to install the new equipment is examined. Multiple scenarios and systems can be examined to conclude to the one that would best suit the vessel and Client’s requirements.

More

- Compilation of Possible Installation Scenarios

- Examination of available resources (i.e. power, pressure head)

- CAPEX & OPEX comparison table

- Optimal arrangement of the new equipment

- Routing for essential piping of the system

- Equipment foundation

- Possible relocation of exist. equipment & examination of most suitable relocation areas

3. Engineering Study

Using the data from the 3D laser scan the fully detailed 3D model of the new installation is developed. This model will be used to generate the production drawings, material lists & approval drawings.

More

- Presentation of the final model to Client for approval.

- Preparation of drawings to be submitted to vessel’s Classification Society for review and approval.

- Preparation of production drawings, to be submitted to shipyards for quotation/ pre-fabrication.

- Preparation of detailed material lists for Client-supplied items.

- Issuing the final specification report for the retrofit.

4. Installation

PSA Marine Bureau’s engineers can attend the vessel’s during system’s installation, to supervise all works and ensure the correct execution and timely completion of the project.

More

- Examine the prefabricated parts for defects & deviations.

- Check the delivery of Client-supplied items.

- Co-ordinate with Shipyard, Client & other service providers to ensure timely completion of the installation.

- Crosscheck the final work done list and claim management.

Latest Projects

M/T "ALIGOTE"

BWTS

ROXANA SHIPPING

TECHCROSS EXECS

1600X1

CLASSLR

"SARONIC SPIRE"

BWTS

SEA SPIRE

ERMA FIRST

1X600

CLASSNK

M/T "ALKIMOS"

BWTS

CAPITAL SHIP MANAGEMENT

ALFA LAVAL PURE BALLAST

3.1 600

CLASSBV